Our greatest fans

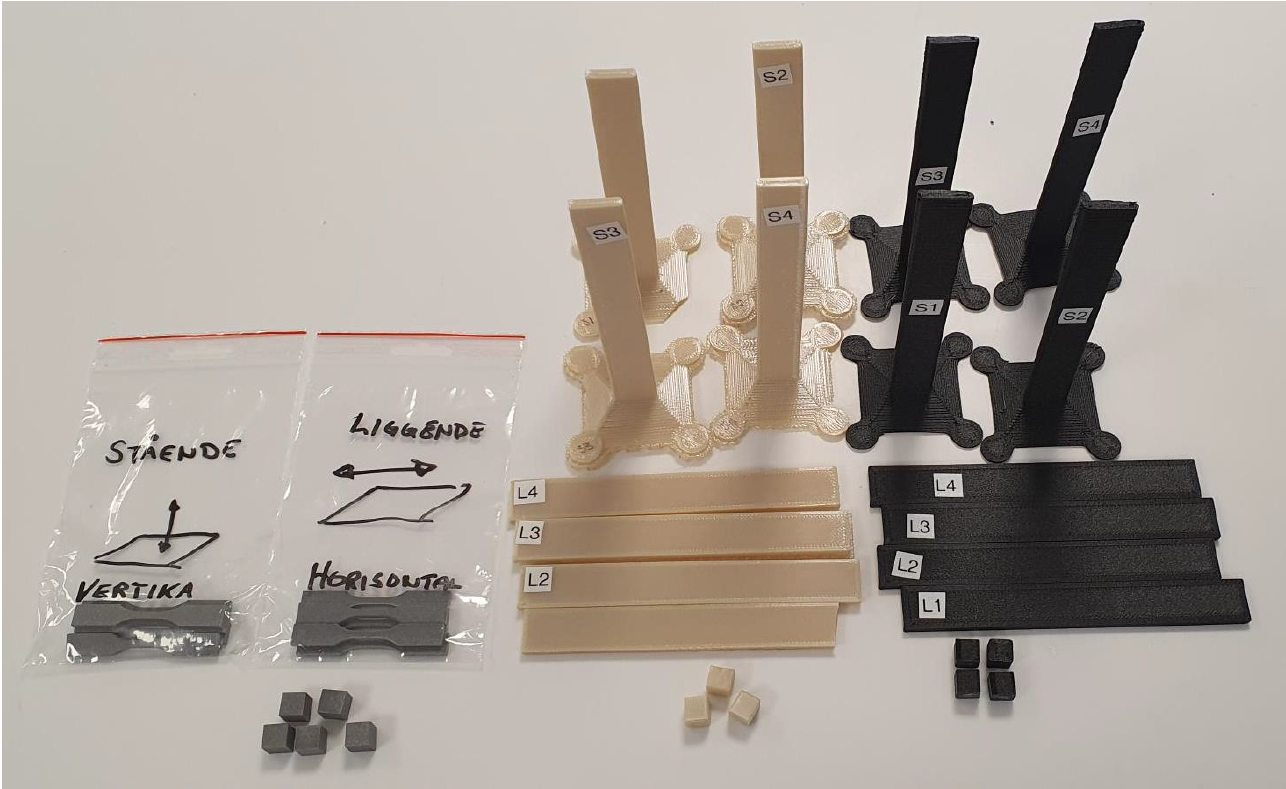

Family of parametric fans parts

The challenge

Degradation & breakdown

Industrial electric motors need cooling. After decades of operation the cooling fans simply wear out. The blades break, the bodies deform and misalign due to constant heat and wear. Keeping a reliable supply of spare parts is a big ordeal.

Lead times

Parts will take months to procure, if the manufacturer even have them in stock anymore. If not, the whole motor will need replacing at considerable cost and down-time.

Fan variations & scale

To further complicate the problem, we are not talking about a single fan model here. There is a myriad of different fans with varying sizes, shapes and specifications. Each manufacturer has their own process for providing parts. Some motor fans are discontinued, or the manufacturer has gone out of business entirely.

Fan manufacturer

Fan variations

Installations

Meeting the challenge

Software

Korall Engineering™ took on this challenge and invented the necessary technology to solve it in the best manner possible.

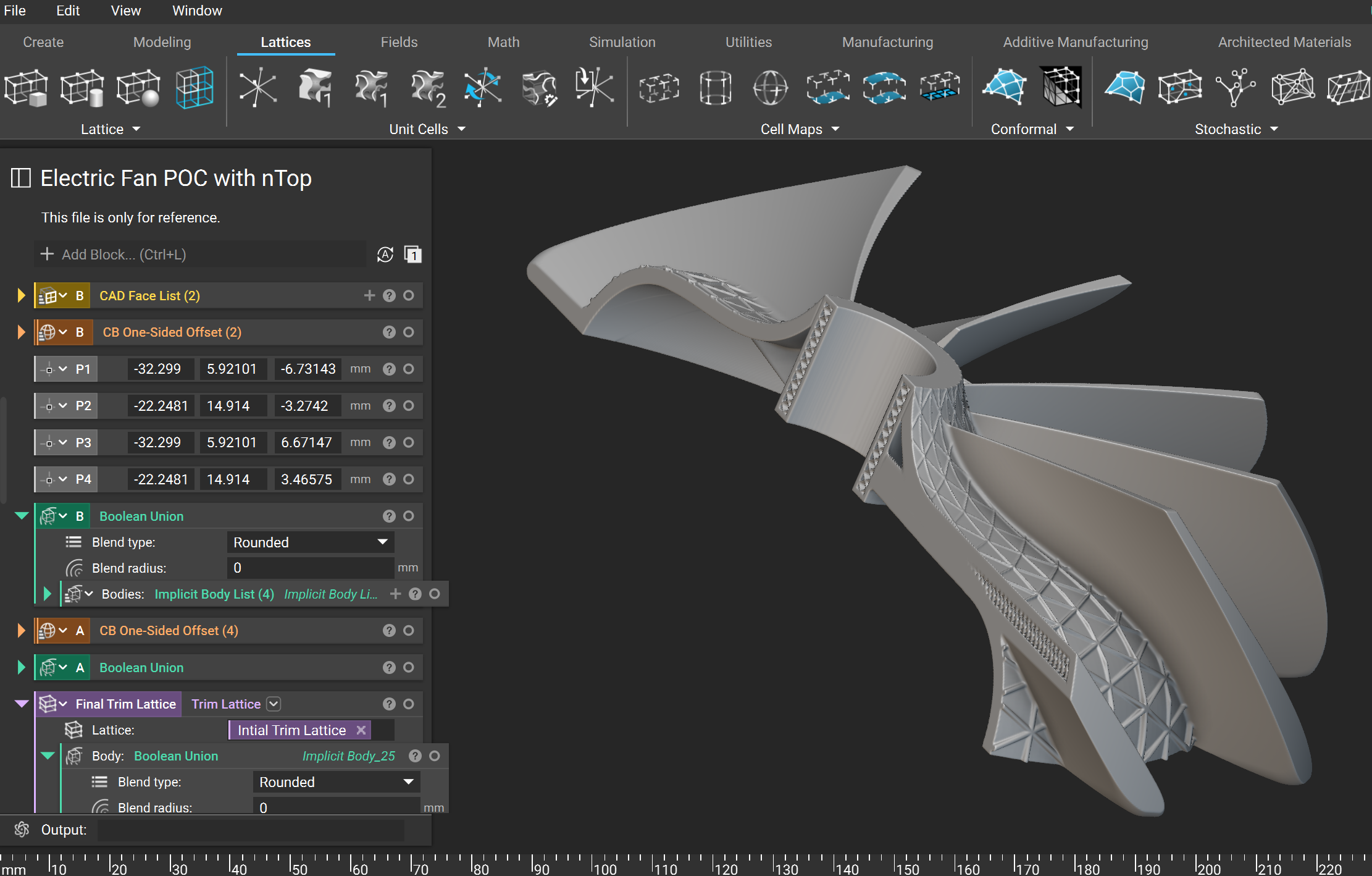

We have developed our own proprietary in-house software that allows us to model and refine families of parts based on parametric models. The parts can be made available in a digital inventory for the end user, making thousands of part combinations available to casual users with no design expertise.

Material choice

First step in designing the fan is to select the right material. This is because the material properties will inform the design constraints.

The main factor in the material selection for this project was to provide a cost-effective material to extend the life of the motors.

Environmental Conditions

- High heat and thermal cycling due to motor operation

- Possible moisture from rain and ocean

- UV-light exposure from the sun

Further constraints for the material relate to environmental impact:

- CO2 footprint of production

- CO2 footprint of distribution

Design process

Designing a parametric model is a data-driven process, so we started by collecting the necessary information about dimensions and specifications from original manufacturers of the fans. We also took the material properties into account.

We then proceeded to digitally sculpt the fan in a proprietary process involving a number of methods such as generative design and ai-driven design to end up with a fully parametric model. This model allows for parameters such as the fan edge and bore diameters to be provided after the model is complete.

Our design tool partners

Our in-house design-automation software can then combine a set of parameters with the model to produce each member in the family of parts, on demand, ready to 3D print whenever the customer needs a replacement fan.

Optimization

Once we have the initial design in place we get to the iterative process of topology optimization.

We run the parts through simulations for mechanical stress and use various proprietary algorithms on the geometry to find redundant material that can be removed without sacrificing the mechanical properties. This saves a lot of material and weight, improving the environmentally impact of the part greatly.

Qualification

Some parts will require a long qualification process. Since 3D printing as a manufacturing method, the materials we had selected and the fan model itself had never been used in an off-shore setting before, there is a requirement to qualify them.

Luckily the fan baldes are low-risk items and so have a reduced qualification process. We can also re-use some of the material qualification from other projects

Manufacturing

While Korall Engineering™ is an expert in additive manufacturing, we don't actually print parts ourselves. We leave that to our expert partners. For the handwheel we used Additech for the dedicated expertise on printing in the polymers

Our 3D printing partners

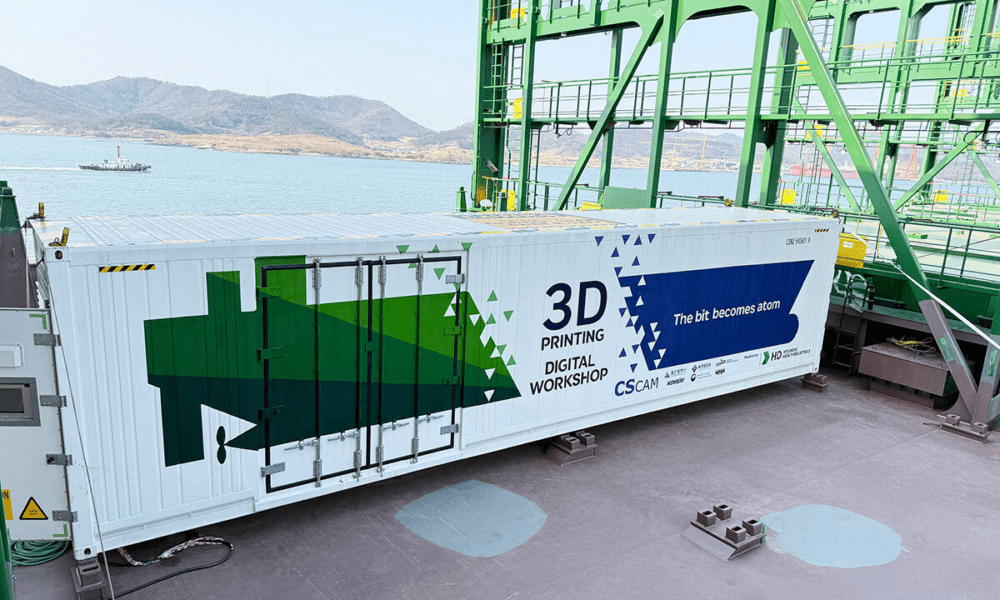

Distribution

One of the strongest advantages of additive manufacturing is distribution, or rather the lack of distribution. There is no long value chain to traverse. Fewer assembly steps. No warehouse full of aging stock.

For critical parts, the manufacturing can be deployed on-site for lead time measured in hours!

Final result

Finally, in production! This is one of many parts that can benefit from the exact same process. Korall Engineering™ ispreparing to handle the growing market.