Reinventing the wheel

Generative family of hand wheels

The challenge

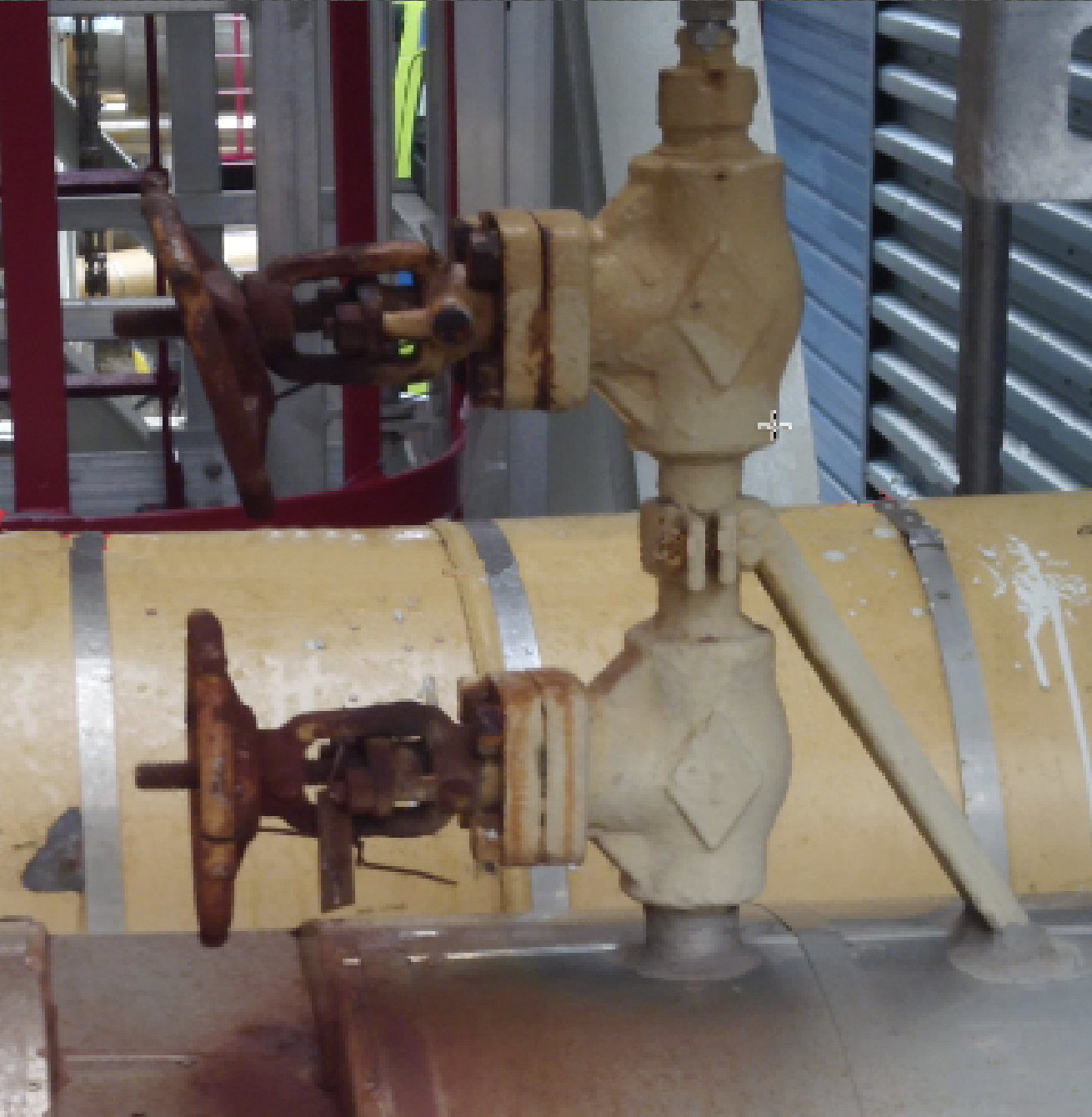

Corrosion

The corrosion of hand wheels that are used to manually operate valves and other equipment on offshore installation in the oil & gas industry is a significant challenge. Constant wet conditions and constant exposure to salt from sea water subsequently corrode the hand wheels to the point of failure, incurring a significant cost.

Lead times

The process from order placement to distribution does not meet the time required by companies for steel valve wheels, as the manufacturing of such parts incur significant lead times. The conditions required to store them are also demanding.

Wheel variations & scale

To further complicate the problem, we are not talking about a single hand wheel. There is a myriad of different wheels with varying sizes, shapes and specifications. Each manufacturer has their own process for providing parts. Some hand wheels are discontinued, or the manufacturer has gone out of business entirely.

Wheel types

Per installation

Installations

Total units

Meeting the challenge

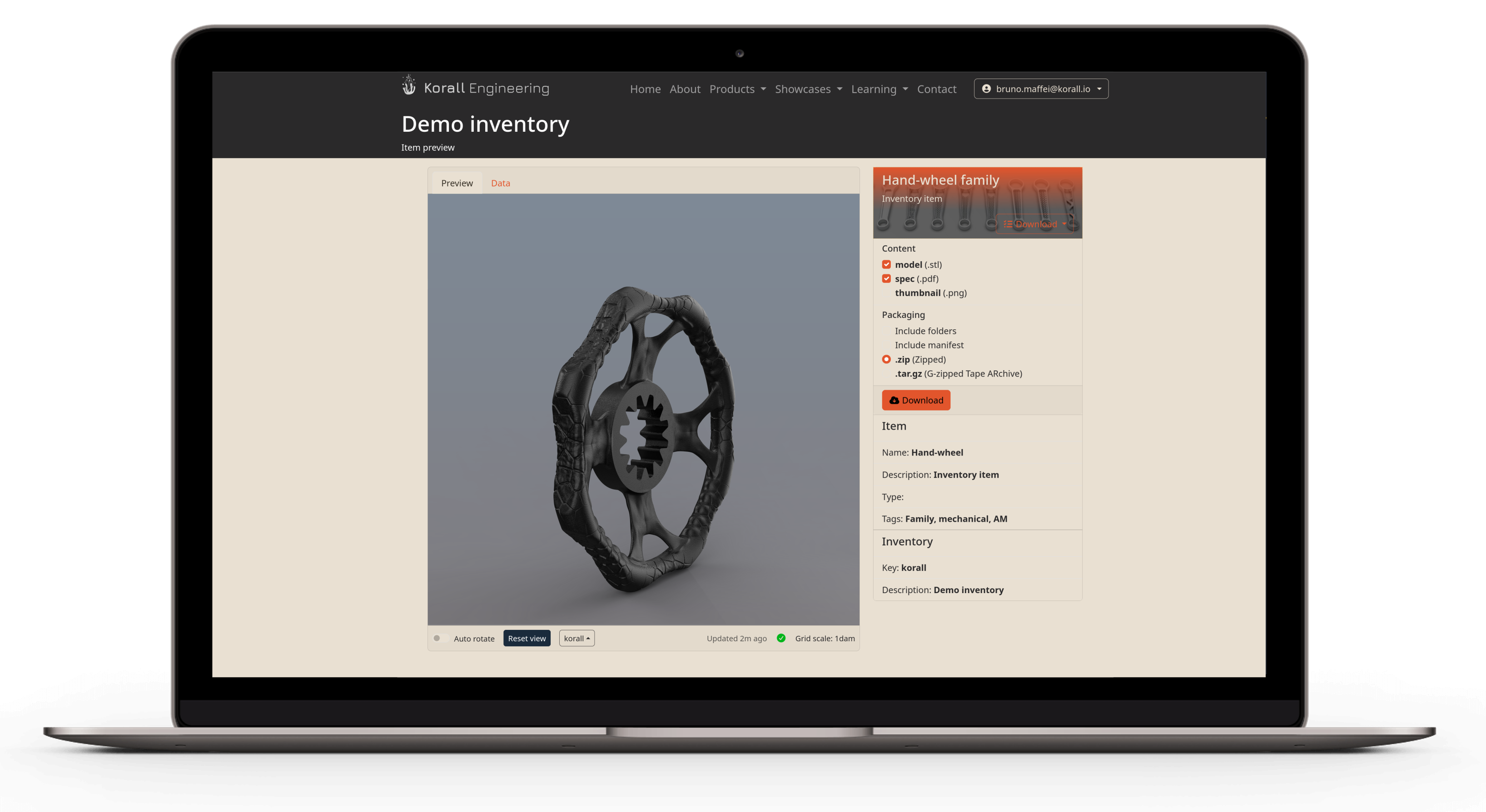

Software

Korall Engineering™ took on this challenge and invented the necessary technology to solve it in the best manner possible. We decided to re-invented the wheel!

We have developed our own proprietary in-house software that allows us to model and refine families of parts based on parametric models. The parts can be made available in a digital inventory for the end user, making thousands of part combinations available to casual users with no design expertise.

Material choice

First step in designing the wheel is to select the right material. This is because the material properties will inform the design constraints.

The main factor in the material selection for this project was of course to avoid corrosion, but we also needed to keep cost at a manageable level while providing the necessary mechanical strength. After considering many materials we settled on a set of advanced polymer materials that can meet the stringent requirements of the environment.

Environmental Conditions

- Salt from sea water

- Constant moisture from rain and ocean

- UV-light exposure from the sun

- Extreme thermal cycling due to rapidly changing weather

Further constraints for the material relate to environmental impact:

- CO2 footprint of production

- CO2 footprint of distribution

Technical Specifications

| Status | Converged |

| Material | HP 3D HR CB PA12 |

| Orientation | Z+ |

| Manufacturing | Additive |

| Volume | 88,202.56 mm³ |

| Mass | 0.088 kg |

| Max von Mises stress | 9.9 MPa |

| Factor of safety | 2 |

| Max displacement | 2.95 mm |

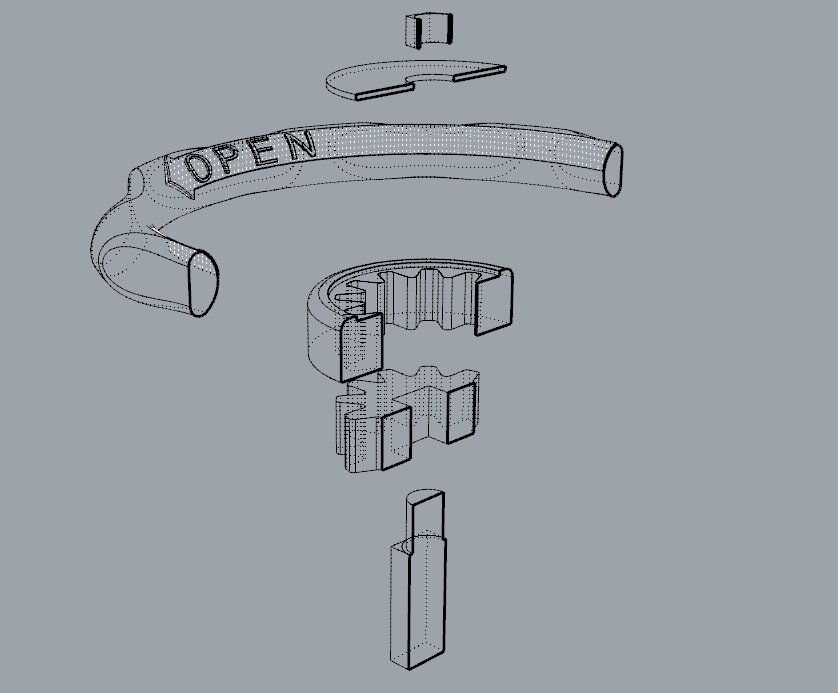

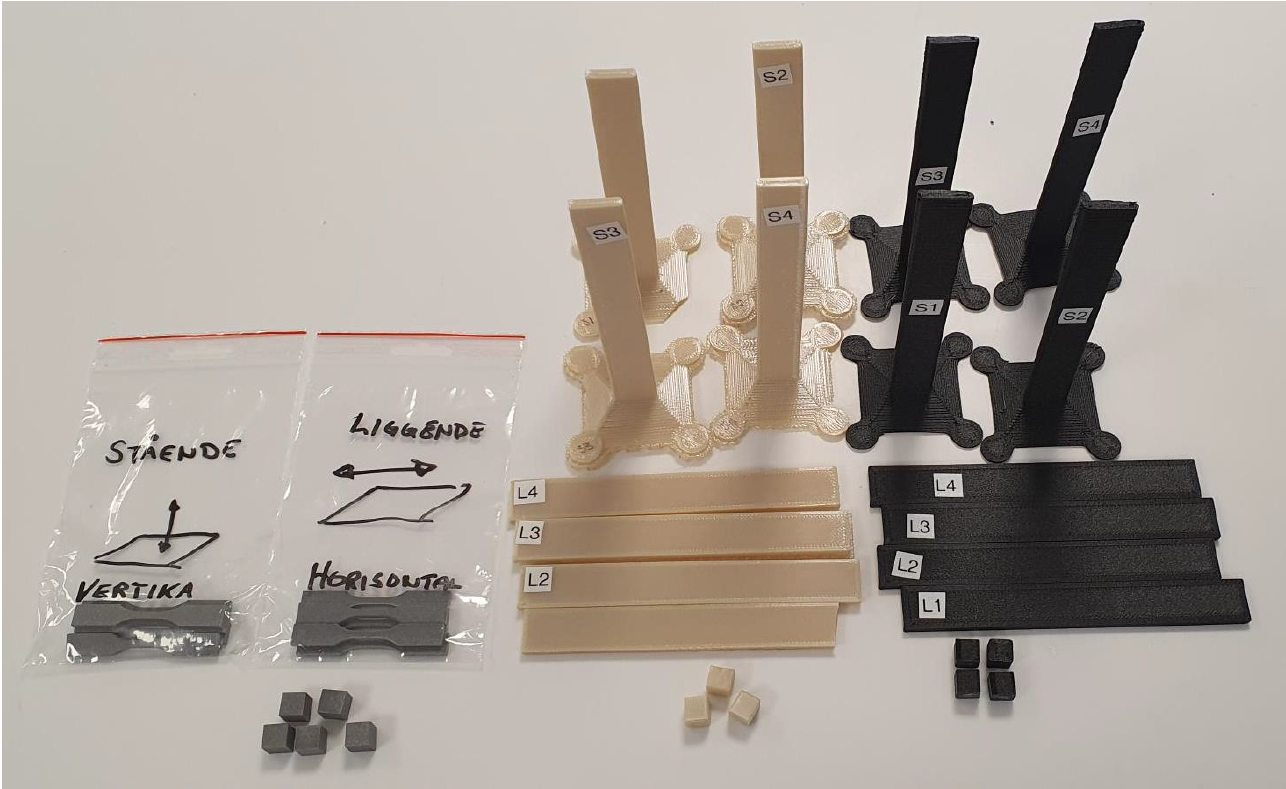

Design process

Designing a parametric model is a data-driven process, so we started by collecting the necessary information about dimensions and specifications from original manufacturers of the wheels. We also took the material properties into account.

We then proceeded to digitally sculpt the wheel in a proprietary process involving a number of methods such as generative design and ai-driven design to end up with a fully parametric model. This model allows for parameters such as the wheel and bore diameters to be provided after the model is complete.

Our design tool partners

Our in-house design-automation software can then combine a set of parameters with the model to produce each member in the family of parts, on demand, ready to 3D print whenever the customer needs a replacement hand wheel.

Optimization

Once we have the initial design in place we get to the iterative process of topology optimization.

We run the parts through simulations for mechanical stress and use various proprietary algorithms on the geometry to find redundant material that can be removed without sacrificing the mechanical properties. This saves a lot of material and weight, improving the environmentally impact of the part greatly.

Qualification

You would be forgiven to think that the process is near completion at this point. Just send the file to a 3D printer and have it ready for production!

Not so fast! Since 3D printing as a manufacturing method, the materials we had selected and the hand wheel model itself had never been used in an off-shore setting before, there is a requirement to qualify them.

This is a long process carried out by our expert partners Nordner and DNV, where they put samples of the materials and products through a battery of physical tests in their laboratory to determine that it will hold up to standards in the field. This is essential to ensure the safety and performance of the end product.

Our qualification partners

In a world first, Korall Engineering™ is proud to have successfully completed qualification, not only for material and product but for a complete family of parts. Due to the substantial cost in time and resources to complete such qualifications, this allows us to license the result to 3rd parties.

Manufacturing

While Korall Engineering™ is an expert in additive manufacturing, we don't actually print parts ourselves. We leave that to our expert partners. For the handwheel we used Additech for the dedicated expertise on printing in the polymers

Our 3D printing partners

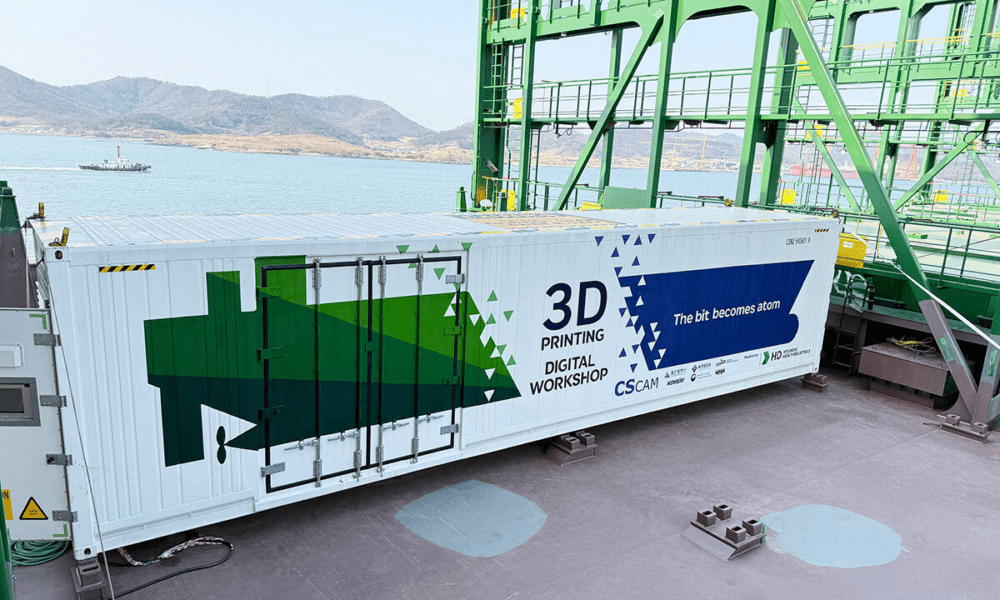

Distribution

One of the strongest advantages of additive manufacturing is distribution, or rather the lack of distribution. There is no long value chain to traverse. Fewer assembly steps. No warehouse full of aging stock.

For critical parts, the manufacturing can be deployed on-site for lead time measured in hours!

Final result

Finally, in production! Here are the results.

| Property | Before | After |

|---|---|---|

| Corrosion resistance | Poor | Excellent |

| UV resistance | Medium (coating) | Excellent |

| Weight | Medium | Low |

| Lead time | 3 - 6 months | 1 - 7 days |

| Production cost | High | Low |

| Downtime risk | High | Low |

| Inventory cost | Warehouse | None |

| Lifecycle | Decomissioning eminent | Lifespan extended indefinitely |

| Environemntal impact | Huge (full mass metal, storage, distribution) | Low (low mass polymer, print on site |

Impact

This is just the tip of the iceberg. While the hand wheel is a humble part, it was selected exactly because of it was a low hanging fruit. This project will spearhead the blossom of an enormous market.

When the floodgates open, Korall Engineering™ is ready to handle the demand with our software ecosystem and our great many friends in collaboration.