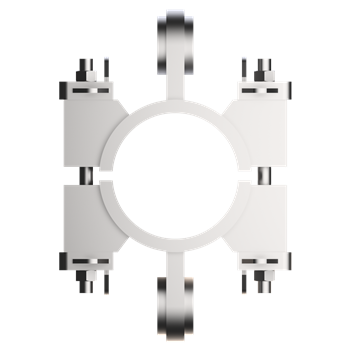

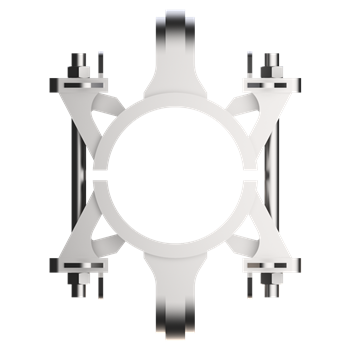

Subsea Riser Clam

As our first projectwe chose a commercially usedSubsea Riser Clampin order to show theadvantages of optimisation AI driven design-to-manufacturing methods withGenerativeDesign, and the benefits of standardisation with Topology Optimisation CAD techniques.

Original

Optimized

We chose this particular product in order to demonstrate how anything can be optimised,made better, even an already heavily standardised machine. Our aimalways remainsthereduction of material use, the increment of efficiency and performance, and the reductionof environmental impact.